>Vehicle Model: FUSO

>Built date: June, 2007

>Chassis model: FV51JK

>Engine model: 6M70

>VIN:JL6ERK6BX7K034727

>>Issue description:

Truck owner reported that the check engine light went on on the vehicle (see picture 1 below). Meanwhile the speedometer failed to function, fuel consumption increased and the speed limiter installed by the fleet often reported speeding.

>>Troubleshooting:

This vehicle is equipped with electronically controlled system, therefore requires the help of FCAR diagnostic tool to inspect and diagnose. The procedures are as follows:

-1. Connect the OBD port and the diagnostic tool with a testing wire.

-2. Locate the diagnostic port (see picture 2 below).

-3. Connect to the diagnostic port and turn the ignition switch to ON. Fig. 1 FUSO

-4. Turn on the FCAR diagnostic tool.

-5. Go to the menu and follow the steps: Diesel Vehicle > FUSO > V5.1 > Engine System > Read Trouble Code > 5280 25 Speed Sensor > Clear Trouble Code > Trouble Code Clearing Completed. Go to Read Trouble Code and if it returns 5280 25 Speed Sensor once more, it means this is a valid trouble code.

>>Issue analysis and inspection:

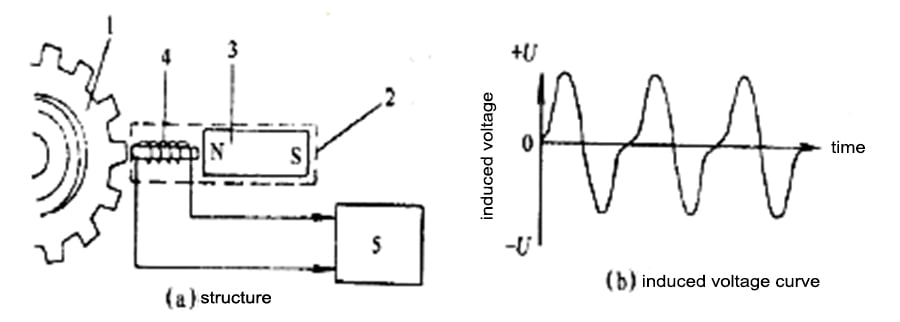

Based on the equipment of the vehicle and the trouble code (5280 25 speed sensor), we can conclude that it’s the result of a damaged speed sensor and malfunctioning wires. The speed sensor diagnostic port is installed on the housing near the output shaft of the auto transmission and is used to detect the rotation speed of the auto transmission’s output shaft. ECU calculates the speed of the vehicle based on the speed sensor’s signals, and offers the results as a sign to shift gears as well as alert the drivers to watch out for speeding.

Steps to inspect the sensor are as follows:

Picture 2 FUSO diagnostic port location

1. On-board inspection. Disengage the wiring harness connector from the speed sensor, and measure the electrical resistance between the sensor terminals with a multimeter. The resistance range of the speed sensors’ induction coil can vary with each vehicle/model, but are typically between hundreds and thousands of Ohms. The resistance of the speed sensors’ induction coil on different types of vehicles can vary, but are generally between hundreds to thousands of Ohms. Jack up the vehicle, make sure the drive wheel is up in the air, rotate the drive wheel and check if there’s pulsed voltage between the sensor terminals with a multimeter. If the multimeter registers a reading of moving pointer, it’s an indication that there is pulsed voltage and that the sensor is well functioning. Otherwise, the sensor is damaged and further inspection should be made to see if the sensor rotor and induction coil are soiled. If yes, clean them first then carry out this test again. If yet again there’s no pulsed voltage detected, the sensor must have broken down and should be replaced. Measuring the pulsed voltage from the speed sensor (see picture 3 below).

2. Parts inspection. Disassemble the speed sensor and measure its output pulsed voltage by following the steps. Walk around the sensor by going towards or against it with an iron bar or a magnet, in the meantime check if there’s pulsed voltage between the terminals of the sensor’s wire with a multimeter. If there’s little to no induced voltage, it means the sensor is damaged and further inspection should be made. Afterwards, carry out this test again. Once confirmed that it’s broken, replace the sensor.

>>Picture 3. Working Principle of the Speed Sensor

1. Parking pawl; 2. Speed sensor; 3. Permanent magnet; 4. Induced coil; 5. Electronic controlled components

>>Debugging:

We checked the speed sensor and found out that there’s no signal output. Then we replaced the speed sensor, started test driving on the road, the check engine light went off and the speedometer was functional. Issue resolved.

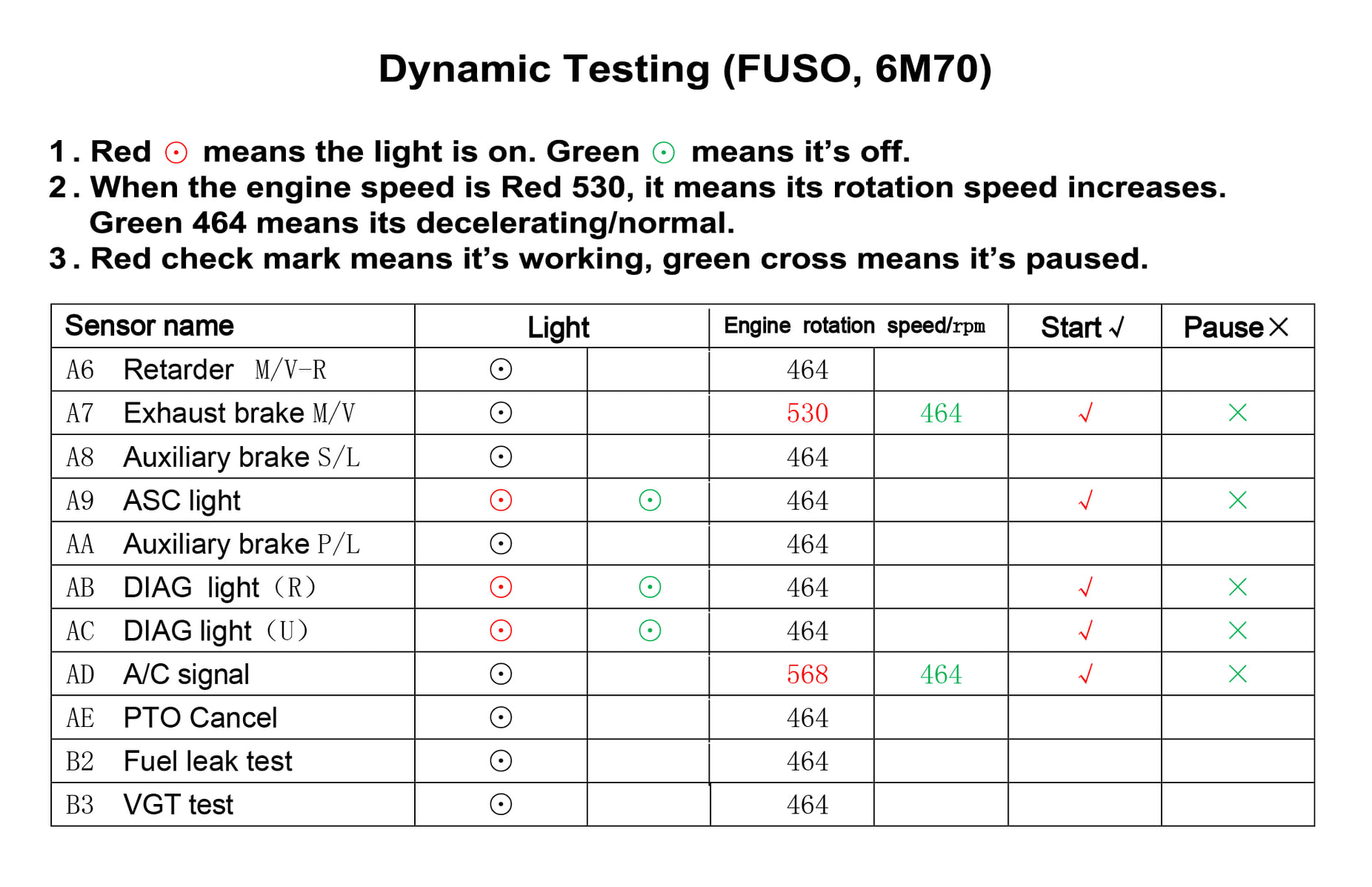

>>Note: Make sure to carry out the dynamic testing when control equipments, sensors and wiring are all functional. Otherwise the test might not work well. If everything is in good shape and the test still doesn’t work, it means this vehicle is not equipped with dynamic testing systems and doesn’t have this feature.

>>Maintenance tips

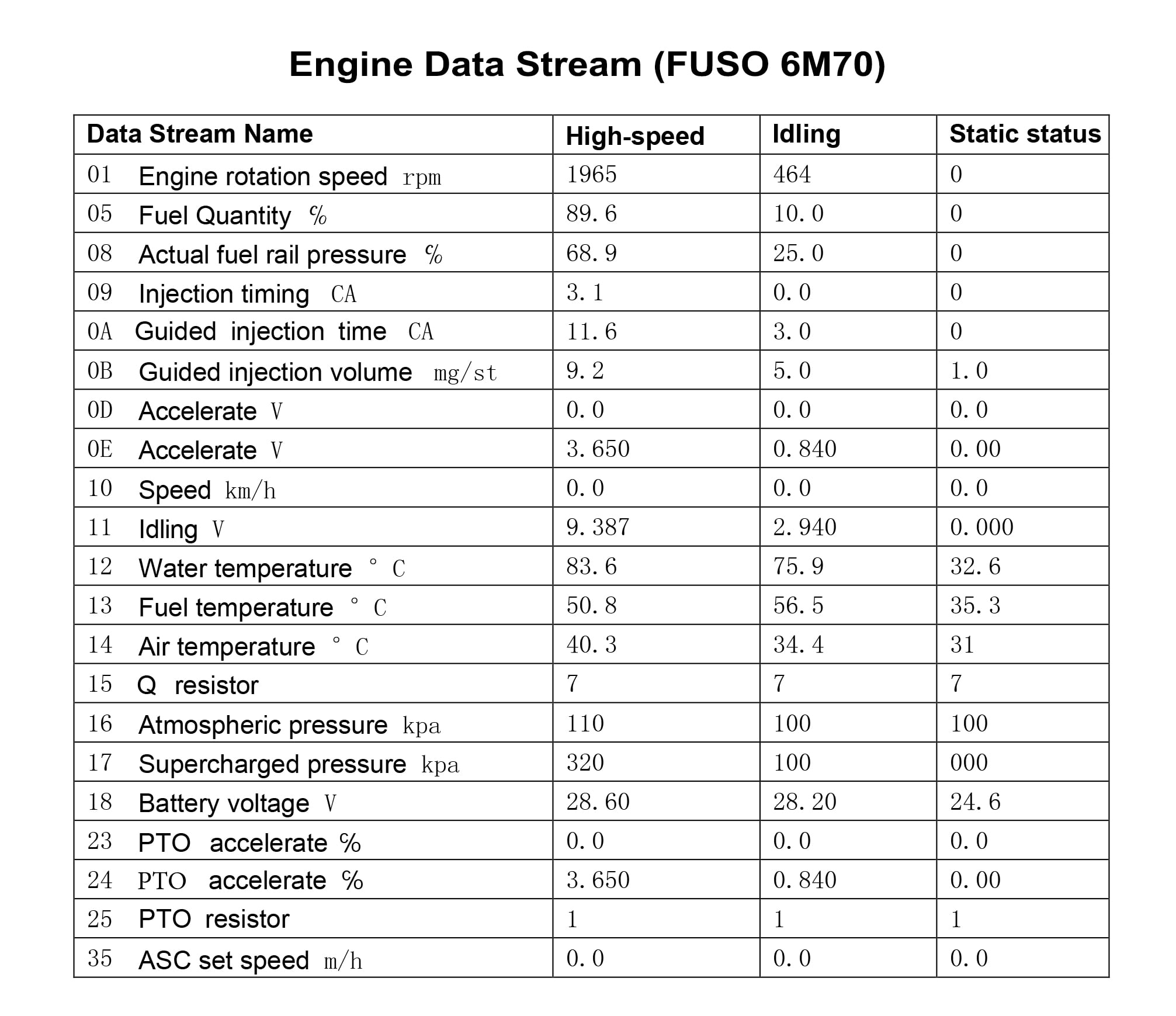

It’s important to be acquainted with the methods and steps to use the diagnostic tool and make a diagnosis before inspecting vehicle engine systems. For instance, in order to tell if a sensor is working or not, we can check the engine data stream, compare engine rotation speed, high-speed, idling speed, static status and its operating status.

Dynamic testing is to check whether the control unit and its components are functioning well. It’s also a way of troubleshooting an issue with the help of FCAR diagnostic tools.